MR-250 Simple miniature chip mounting machine

MR-250 Simple miniature chip mounting machine

Features

- It realizes automation of simple work at low cost.

- Portable Mobile Size.

- Easy operation to understand intuitively.

Dispense / Mount

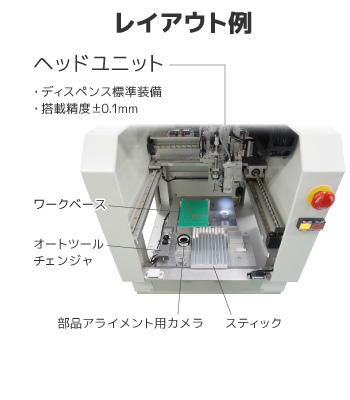

The head part is equipped with a coating / mounting function as standard, 1005 chips can be mounted with mounting accuracy of ± 0.1 mm, exclusive collet automatic replacement mounting corresponds to other parts. It can be used as a low price chip mounter. Additional options such as automatic image processing function, conveyor specification, heating function etc. further extend the possibility of MR - 250. Especially when heating function is added, it can be used as low price version MRS - 850.

Ultra small size and light weight

With the new design pursuing place efficiency, all functions fits into the size of two cases of beer case. The weight of about 25 kg of the body realizes "compact mounter" with its compactness.

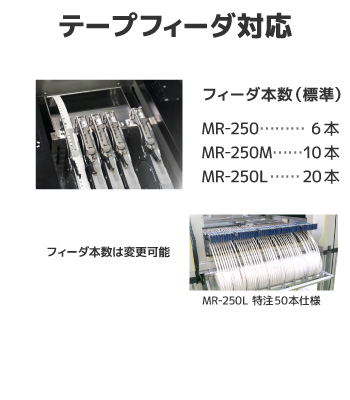

Supply of parts

Ten tip sticks capable of supplying 8 mm cut tape are included as standard (20 MR - 250 M). For tape feeders also available for option, usually 5 (MR-250M for 10 mm) for 8 mm tape can be set.

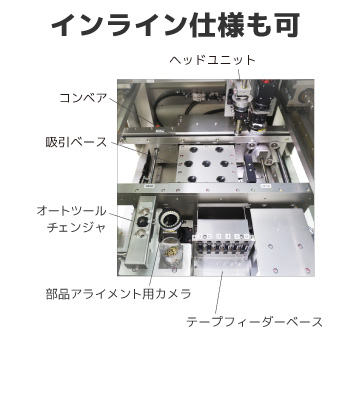

Conveyor compatible

While it is compact size, it also demonstrates its full potential in production lines. It can also be used as chip mounting machine or simple mounter with IC tag and zero Ω resistor mounted.

Usage example of MR-250

|

|

|

|

|||

| LED mounted | Testing mounting of chip parts | Equipped with post-attached resistor | Testing the mounting of connector parts |

Spec

| model | MR-250 | MR-250M (M size compatible) | MR-250L (L size compatible) |

|---|---|---|---|

| body size | Width 460 X depth 700 X height (550) [mm] (desktop standard) | Width 690 X depth 780 X height (550) [mm] (desktop standard) | Width 960 X depth 1150 X height 1400 [mm] (independent type only) |

| weight | About 40 [kg] | About 55 [kg] | About 550 [kg] |

| Mounting precision | ± 0.10 [mm] | ||

| Work size | Maximum 150 X 150 [mm] | Maximum 250 X 330 [mm] | Maximum 510 X 460 [mm] |

| Work thickness | 1.0 to 2.4 [mm] | ||

| Supply of parts |

|

|

|

| Alignment method | Exclusive collet*, automatic image processing*, stage alignment* | ||

| Other |

|

|

|

| Power supply / air | AC 100 V, 50/60 Hz, 0.4 to 0.6 MPa | ||

| List price | 2,800,000 yen ~ | 3,800,000 yen ~ | 6,500,000 yen ~ |

| Main Options | Automatic image processing, Load cell, Conveyor specification (Inlining), Standard / Simple stage, Standard transfer unit / Simple transfer base, Rough supply specification, Tape feeder, Part feeder support, Solder ball mounted specification, Dispensing controller, Point reflow, Heat Crimp unit, loader / unloader, signal tower, area sensor | ||