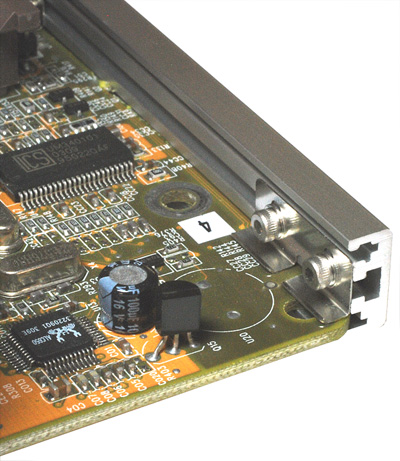

Standard dip cover (DCE1), the dip cover controls circuit board warpage caused by factors such as heat and protects the circuit board from harm such as solder fogging and static electricity

ORDER: Distributors

Watch the DCE1 video

| 23.5MB |1 minute and 42 seconds |

|---|

|

| The 3 features of DCE1 (Japanese version only)(WMV file) |

Features

For various types of small quantity production

One of these can support types with differences in configuration.

Self processing is also possible

This can be cut to the length of your preference due to the aluminum material.

Moveable weight springs

It is possible to attach the weight springs for each type of configuration to the area of your preference with the center part M2 nut groove.

Other

- This prevents solder fogging and circuit board warpage.

- Repetitive use is possible.

- This is Rohs compatible.

| Carrier hold | Prevention of circuit board warpage | Prevention of solder fogging | Flow tank | Reflow oven | Cutter |

|---|---|---|---|---|---|

| unacceptable Can support DCHF and DC |

good | good | good | good | unacceptable |

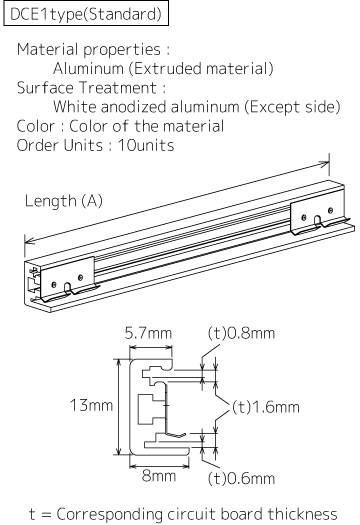

Product Specifications

| Quality of Material | Aluminum (Extruded material) |

|---|---|

| Surface Treatment | White anodized aluminum (Standard) |

| Corresponding circuit board thickness (t) | Thickness: 0.6mm/0.8mm/1.6mm Can be used at a ± 0.1 dipping depth ≤ t |

| Heatresistance | 260゚C within 2 minutes/ (without pressurization) max |

| Number of Uses | Over 200 times (used repeatedly at 245゚C soldering at a 4 second interval) |

| Rohs | Compatible |

Standard Size List

| Model Number | Length(A) | Corresponding circuit board thickness (t) | Insertion Depth (B) | Number of springs | Shape |

|---|---|---|---|---|---|

DCE1-100-2X |

100mm | 0.6mm 0.8mm 1.6mm |

For 0.6t:6.0mm For 0.8t:4.0mm For 1.6t:3.0mm or 4.5mm |

2 |  |

DCE1-150-3X |

150mm | 3 | |||

DCE1-200-4X |

200mm | 4 | |||

DCE1-250-4X |

250mm | 4 | |||

DCE1-300-5X |

300mm | 5 |

* Weight springs sold separately

The minimum lot is 50 sets/1 type. The spring width is 20mm and is fastened with 2 M2 (CS) screws + nuts.

Precautions when using

- Do not pass through the lead cutter.

- Use within a frame temperature of 245゚C.