SMT Solution

SMT Solution

Composition unit

ST-310F

Manual cream solder printer

MR-250

Simple miniature chip mounting machine

APR-20A

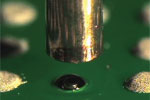

Contactless Point Reflow

Easy to operate, Become immediate fighting force, But low price

We are offering 3 packages total pack of printing, mounting and heating mounting for people looking for low price, space saving implementation solution. It is a proposal that is possible because it is Okuhara electricity which develops, manufactures and sells up.

Total price: $36,700

- Printer: ST-310F

- Mounter: MR-250

- Reflow: APR-20A

Printer: ST-310F

$3,300

Mounter: MR-250

$26,000

Reflow: APR-20A

$7,400

Possibility to spread by option

Various options are prepared for each product. Some examples of the configuration are introduced.

* * *

ST-310F option ex.

Double-sided board$4,650

- ST-310F main unit

- Double-sided board base

- Backup pin (10units)

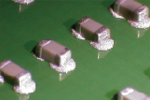

MR-250 option ex.

Automatic image processing$45,800

- MR-250 main unit

- Automatic image processing

- Suction nozzle (for 1005 chips)

- Tape feeder (8mm tape X 3)

APR-20A option ex.

Multi-point simultaneous heating$8,750

- APR-20A main unit

- Multi-point heating nozzle

- Lower surface sub heater

ST-310F option ex.

Flexible board$5,850

- ST-310F main unit

- Suction base

- Suction pump

MR-250 option ex.

Conveyor$51,300

- MR-250 main unit

- Conveyor

- Automatic image processing

- Suction nozzle (for 1005 chips)

- Tape feeder (8mm tape X 3)

APR-20A option ex.

Automatic heating$24,000

- APR-20A main unit

- Automatic XY axis

- PC Control

* * *

The options listed here are just examples. If you have "ideas" , please do not hesitate to contact us.

Production line in a small space

With compact design, three models can be installed as a system in a standard work table (1800 x 900 mm). From now on you can use the implementation line as "mobile" sense. It is flexible enough to respond to cell production where product items change frequently.

More useful, more helpful

- To introduce a line though it puts only one chip...

- Installation precision is unnecessary but expensive high-precision loading machines only...

Currently, there are many parts that are overfilled in the production line.In addition, there are places where equipment is not installed due to simple because of mounting test etc. in quality inspection by parts manufacturer. With Okuhara Electric's implementation solution, cost reduction has made it possible to assist the field where automation was difficult so far.

Automatic mounting of adjustment resistor

Testing mounting of chip parts

Equipped with PoP

Like a dream? No, it can be realized.

- As a marking device rather than chip mounting...

- I hope it will be possible to mount only specified parts for each board...

- If you can communicate with this device...

Please feel free to contact us if you have any request. We will shape your "ideas".

Direct mounting on leads

Solder ball collective loading

Coil joining

Composition unit

ST-310F

Manual cream solder printer

MR-250

Simple miniature chip mounting machine

APR-20A

Contactless Point Reflow