Compact SMT Line

Compact SMT Line

One line about from $55 thousand

In the future "manufacturing"

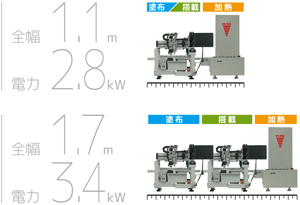

- Super compact design with a total length of 1.1 m

- Easy to realize the layout configuration according to production takt and mounting conditions.

- With standard work desk space, you can easily make production lines. (Standard working machine length: In the case of 1.2 m)

Composition unit

MR-250

Simple miniature chip mounting machine

VR-350

Through batch simple reflow oven

Eco-design with space saving and energy saving

Mounter weight is about 40 kg, reflow oven is about 30 kg. Since it can be carried easily with 2 people, you can choose the installation location. Since two units fit in space-saving, it is easy to make a production line anywhere. Also, two ultra-compact simple chip loading machines MR-250 can be used side by side, can be used as a dedicated coating machine and dedicated machine, or can be used as a coating / mounting mixed machine. You can flexibly combine the optimal mounting lines at any time to meet your production needs.

Mounter weight is about 40 kg, reflow oven is about 30 kg. Since it can be carried easily with 2 people, you can choose the installation location. Since two units fit in space-saving, it is easy to make a production line anywhere. Also, two ultra-compact simple chip loading machines MR-250 can be used side by side, can be used as a dedicated coating machine and dedicated machine, or can be used as a coating / mounting mixed machine. You can flexibly combine the optimal mounting lines at any time to meet your production needs.

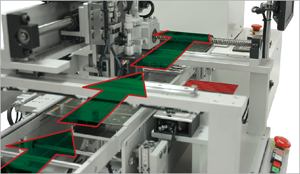

Automatic continuous production of small lot boards by adopting conveyer

Although it is a tabletop device, a conveyor is standard equipment. Maximum □ 150 mm size substrates can be accommodated, making it ideal for small lot production such as simple LED board production, FPC mounting, test mounting lines at parts manufacturers. This can be realized by automation of simple work which was expensive and difficult to automate so far.

Although it is a tabletop device, a conveyor is standard equipment. Maximum □ 150 mm size substrates can be accommodated, making it ideal for small lot production such as simple LED board production, FPC mounting, test mounting lines at parts manufacturers. This can be realized by automation of simple work which was expensive and difficult to automate so far.

Operability is top priority

For intuitive understanding, emphasis on easy operation. You can use it as an immediate fighting force from the day you set it up. The operator selects data and only presses the start switch. MR-250 and VR-350 cooperate to carry out continuous production of a predetermined number of sheets.

Start with less investment

One line can be constructed at a cost of about 1/5 of the general production line. As it is only necessary to add another line as needed as production type and production volume increases, it is possible to start up smoothly with reduced initial investment.