Contactless Point Reflow APR-20A、Semi-automatic pencil reflow which can solder the 0402 chip with ease

ORDER: Distributors

Features

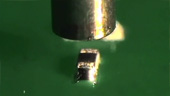

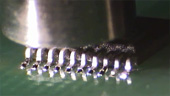

Reflow FunctionThis function enables soldering at the minimum heated air flow without blowing off minute parts such as the 0402 chip. This is optimal for soldering in the narrow pitch mounting. |

|

|

|

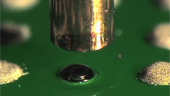

Rework FunctionWith this function minute parts with a 1005 size chip or less can be removed with ease. This is optimal for narrow pitch mounting repair. |

|

Easy Position DeterminationThe heating center is guided by light. The center of the minute parts is accurately determined.* Accuracy depends on part size. |

|

|

|

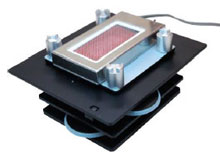

Assistant HeaterMulti-layered circuit boards and ceramic circuit boards which have difficulty in raising their temperature can be supported through using an assistant heater from the bottom. |

|

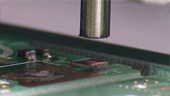

Complete control of heating rangeIt is possible to change the heating range from 0402~QFP to multipoint heating with various optional nozzles. Moreover, replacement of the nozzle is very easy with screw type. |

|

Various optional nozzles |

Batch heating nozzle |

Watch the APR-20A operation video (WMV file / JP)

-

1.7MB / 13secNarrow range heating possible.

-

2.7MB / 23secHeating to the 0402 chip.

-

1.3MB / 9secSoldering can be carried out with ease by anyone.

-

1.4MB / 10secOperation is carried out by only pushing the start switch.

-

2.5MB / 19secAutomation is possible through special orders.

-

1.7MB / 13secPossible to register up to 50 items in the heating data.

-

1.4MB / 10secSimple position adjustment with the laser beam guide even when carrying out operation manually.

-

3.6MB / 32secRework of 0603 chip.

-

2.0MB / 13secWhen heated at a time of about 5mm square.

-

2.0MB / 16secBatch heating nozzle.

-

3.3MB / 24secSoldering of insert parts

-

2.3MB / 23secHeating of SOP

-

1.6MB / 9secHardening of adhesiveNEW

-

4.6MB / 28secSoldering of insert partsけ(MRS)NEW

Product Specifications

APR-20A Main body specifications

Correspondence to M size board, automatic point reflow (MH-250) is also possible.

| Model | APR-20A |

|---|---|

| Main body size (length x width x height) | 345 x 365 x 380mm |

| Weight | Around 20kg |

| Target circuit board size | 40 x 40-200 x 170mm |

| Heating method | Hot air method (250W) |

| Maximum heating temperature | 450℃ |

| Standard attachments | 1 nozzle (supporting 0402 chip - 1005 chip) / 1 CA sensor |

| Cycle time (depending on the built-in circuit board) |

Heating: 4-10sec/chip |

| Operation switch | Mode change, Select, UP, DOWN, Enter/Start/Stop |

| Power source/Air | AC100V, 0.4~0.6MPa |

| Heating gas | Atmosphere / N2 |

Options

| Work stage | PWS-20(XY stage part) |

|---|---|

| Assistant Heater | 100V / 100W (temperature setting max is 150℃) |

| Heating nozzle | For 1608-2125 chip usage / For 3mm opening usage / 2-hole type |

PWS-20 (XY stage part)

| Target circuit board size | Opening 40-200 x 170mm / t=1.6 (Sizes other than the standard specifications are optional) |

|---|---|

| Circuit board securing method | Magnetic moveable circuit board supporter / Height 25mm x 4 supporters |

| XY moveable parts | Knob operation / Movable stroke (X,Y) = (±30, ±50)mm |

| Stage part size (length x width x height) | 250 x 250 x 55㎜ |

| Stage part Weight | Around 2kg |