VR-350 Through batch simple reflow oven

VR-350 Through batch simple reflow oven

Features

- Performance equivalent to large conveyor type reflow furnace

- Total length 550 mm

- Rapid temperature rise

- Significant reduction in preparation time and cooling time

Small and space-saving desktop type. Nevertheless, Performance equivalent to that of large conveyor type reflow oven!

Profile creation freely

By batch type control, it is possible to create profiles of up to 10 zones. A profile equivalent to a large conveyor type can be easily executed.

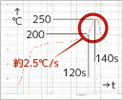

Rapid temperature rise

With our proprietary heating system, we achieved rapid temperature rise of about 2.5 ° C / s in a standard single layer 1.6 mm glass epoxy board. High temperature solder can also be accommodated.

Significant reduction in preparation time and cooling time

There is no "waiting time" in large reflow. It is an energy-saving design that does not use the extra electric power until the completion of preparation and cooling.

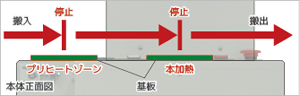

Through batch system adopted

Adopts a through batch system that uses space-saving specialty of batch type and production efficiency as conveyor type specialty together. We reproduced the performance and productivity of the large conveyor type in the full width of 500 mm.

Spec

| body size | Width 550 X depth 750 X height 750 [mm] (desktop only) |

|---|---|

| weight | About 30 [kg] |

| Work size | Maximum 150 X 200 [mm] |

| Heating method | IR heater |

| Work temperature rise capability | About 2.5℃./s (single-layer glass epoxy substrate d = 1.6 mm) |

| Temperature distribution | ± 10℃ |

| Temperature accuracy | ± 10℃ |

| Temperature measurement | K type thermocouple |

| Profile | Maximum 10 steps, input item: set temperature / heating time |

| Power supply / air | AC 200 V (single phase), air unnecessary |